Sister Ruth Starman opens the door to a red brick building on the sprawling 500-acre campus of the Benedictine Sisters of Perpetual Adoration. She wants to show me the convent’s “big baker.”

We’re in rural Clyde, Missouri, but it feels like Italy. Imposing turrets and steeples peek out above stalks of corn and grassy meadows. A water tower stands out front, and a pond to the east is stocked with bass and bluegill. Bells ring throughout the day.

Inside the red brick building, the mood is just as peaceful.

Storage boxes dot the floor, and the massive baking machine hulks in the corner, unused. Starman, who’s wearing a black veil and has a silver cross dangling from her neck, says the sisters are trying to resell some of the equipment.

Sister Ruth Starman, a former medical researcher in Maryland, was drawn to the Benedictine Sisters because of their focus on the Eucharist. (The Hustle)

Just a few years ago, the place was a bustling enterprise.

After morning prayers, the nuns baked communion wafers here, sometimes churning out more than 2m of the coin-shaped pieces of bread in a week and shipping them to clients ranging from parishes to prisons to Princess Cruise Lines.

Communion wafers used to be almost entirely produced by nuns running small-scale operations like this. They provided an integral role in developing a product that they, along with the rest of the Roman Catholic Church, believe is turned into the literal body of Christ at mass.

But today it’s a different story.

Now, almost every communion wafer comes from the for-profit Cavanagh Company, the United States’ altar bread monopoly.

When communion wafers were made local

Nuns have been entrepreneurs since before anybody used the word “entrepreneur.”

They started hospitals and schools in the 19th century, engaging in the labor market when most women were barred from working outside the home. In recent years, nuns have done everything from breed horses to open a pizza restaurant in Cincinnati.

Nuns like the Benedictine Sisters differ from those who run hospitals or schools. Their focus is contemplation and prayer for the salvation of the world. Nearly all day in Clyde, at least one sister prays in the chapel.

But one cannot live on prayer alone. Like everyone else, the nuns must pay for shelter, utilities, food, and clothing.

The Benedictine Sisters of Perpetual Adoration started a convent in northwest Missouri in 1874 when five sisters immigrated from the Swiss Alps. (The Hustle)

So in 1910, the Benedictine Sisters of Perpetual Adoration started producing communion wafers — “an almost ideal type of work for cloistered, contemplative communities,” Starman said.

By the 1920s, hundreds of orders of nuns, from the Poor Clares to the Passionists to the Sisters Magdalens, were also making bread, usually just enough to sustain living expenses and keep local churches stocked.

Among the various orders, the Benedictine Sisters always stood out.

- In 1927, they produced 1m wafers for a Eucharist Congress in Chicago.

- By 1955, the order’s monasteries in Missouri; Tucson, Arizona; and Mundelein, Illinois, made ~50m wafers, or one-seventh of the ~350m wafers consumed in the US.

The work was never easy. For the first half of the 20th century, they cut each host individually. During the Christmas and Easter season, when far more Christians attended church services, the nuns would be up until midnight, baking away.

As any nun who ever made a communion wafer knows, the reward greatly outweighed the burden.

The rise of Cavanagh

John F. Cavanagh was a man who liked to tinker around.

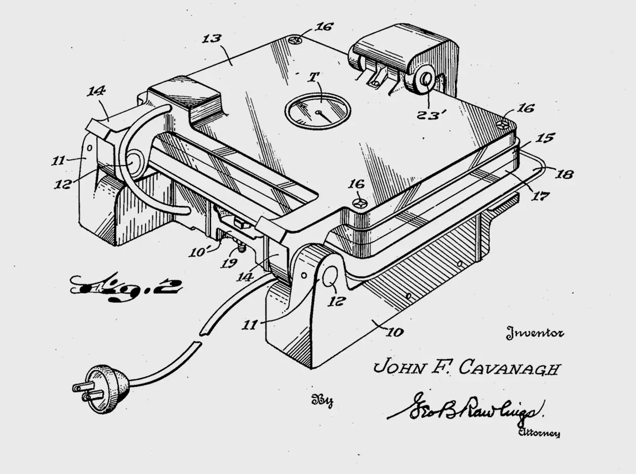

Type his name into a database for patents, and you’ll find dozens of inventions connected to him, everything from a hat rack to a staple remover to a power-driven toothbrush.

In the 1940s, his sons once recalled, a Rhode Island priest approached Cavanagh asking for a favor: Could he build a machine that would allow nuns to bake and cut communion wafers at a wider scale?

The resulting product was known as the Cavanagh Baker, a piece of equipment purchased by hundreds of convents to great acclaim, so much so that one group of Boston nuns devoted prayer hours to Cavanagh.

One of Cavanagh’s early wafer-baking machines. (US Patent Office)

The timing coincided with a sea change in the Catholic Church.

Previously, churchgoers participated in communion monthly; around this time they started partaking weekly. At one point, the Tucson Benedictine community saw altar bread sales increase 45% year over year.

In the late 1940s, Cavanagh handed over the company to his sons, John Jr. and Paul, who soon had an idea for expanding the business and filling the church’s increased needs for wafers: baking the altar bread themselves.

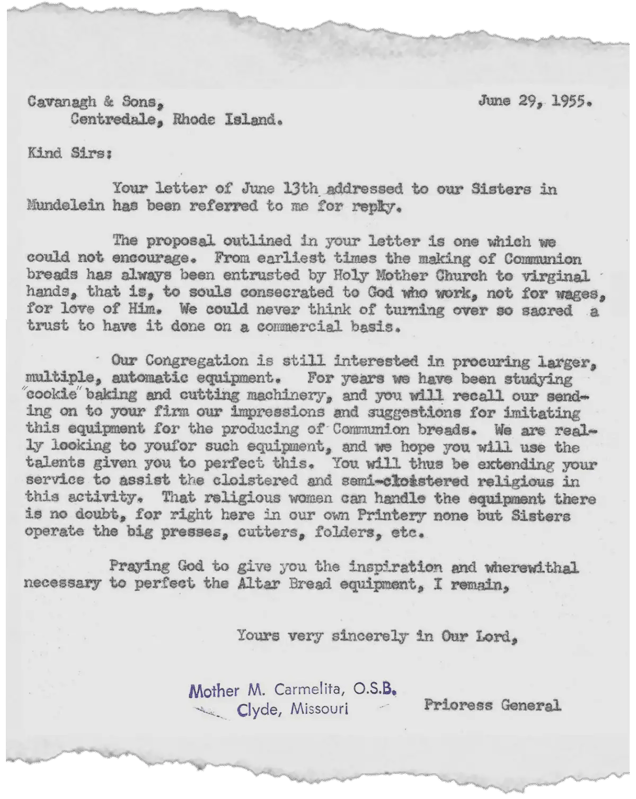

John F. Cavanagh Jr. wrote a letter to the Benedictine Sisters’ Illinois community in 1955, saying they had gotten approval from their local bishop in Rhode Island to start wafer production. He said he wanted to supplement nuns’ work, not compete with them.

In the letter, which was provided to The Hustle, he also suggested it would be “impractical for nuns to purchase, operate, and maintain” increasingly large and complex machinery.

The nuns weren’t so sure it was a good idea. The Benedictine Sisters’ leader, Mother Mary Carmelita, wrote back, saying they “could not encourage” the company’s proposal.

“We could never think of turning over so sacred a trust to have it done on a commercial basis,” she wrote.

A letter sent to Cavanagh by the nuns (Benedictine Sisters of Perpetual Adoration)

As for the heavy machinery? The Benedectine Sisters handled printing presses, and they had been studying new cooking and cutting methods for years — they had even sent the Cavanagh company their impressions and suggestions regarding equipment.

Fearing dozens of religious communities could lose their livelihoods, Carmelita sent letters to 17k parishes and communities in 1956, advertising their prices and ensuring they could fulfill their altar bread needs.

Meanwhile, the Cavanagh brothers pushed ahead with their business expansion.

The company produced ~50m wafers in 1956 and grew their production to ~400m by the late 1970s and ~1B in the 1990s, enough to command ~75%-80% of the market.

Some major innovations allowed Cavanagh to stand out:

- The company developed a larger host that was imprinted with cross designs and tasted more like real bread than previous types of wafers.

- It also patented a seal-edged design that made wafers less likely to crumble.

“We patented the process and kept out competitors to maintain a lion’s share of the business,” Paul Cavanagh later told the Providence Journal.

A representative from Cavanagh declined an interview request with The Hustle.

As Cavanagh’s business increased, most convents — many of which suffered from declining enrollment and found it harder to sustain their extracurricular businesses — stopped baking wafers.

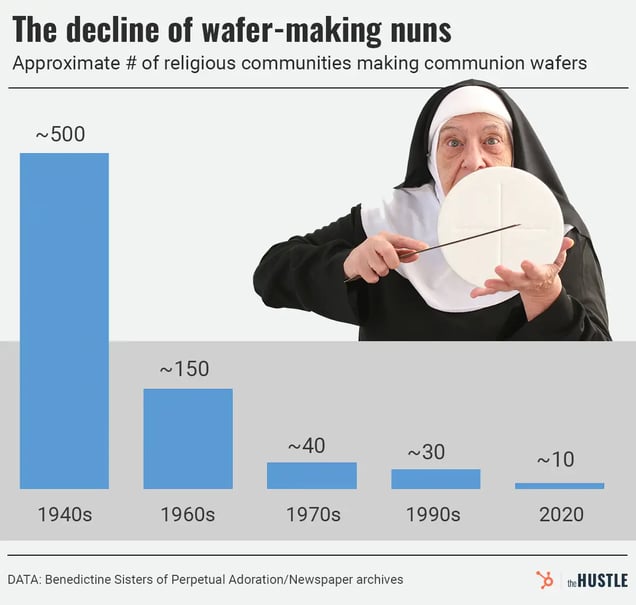

The number of religious communities that made wafers dropped from ~500 in the 1940s to ~150 in the 1960s to ~40 by the late 1970s. Roughly 30 convents were making altar bread by the 1990s, according to Starman.

Zachary Crockett / The Hustle

Those that stopped altar bread production often started working with Cavanagh, buying wafers wholesale and selling them to parishes. (Cavanagh does not sell directly to Catholic churches.)

Despite the collegial relationship, some nuns coped with a loss of livelihood and a feeling of powerlessness against a budding monopoly.

As the Franciscan Poor Clares of Brenham, Texas, explained on their now-defunct website, according to a story by writer Rowan Moore Gerety, Cavanagh, “that big monstrous secular competition,” was always a step ahead.

“They made whole-wheat breads. We learned to make whole-wheat breads. They made theirs a fraction larger. We had a machine built that would cut them larger. They made theirs a little thicker, with a cross incised in the middle. We couldn’t copy that,” wrote the nuns.

The Benedictine Sisters beat the odds

In the early 1990s, according to the Benedictine Sisters, Cavanagh employed another tactic to drum up business, sending postcards and altar bread samples to nearly every parish in America.

The “mass marketing,” as Sister Ruth Starman described it, laid out the advantages of using Cavanagh: lower costs because of its sizable operation and more convenient packaging. The company emphasized a modern style, promoting its product as untouched by human hands.

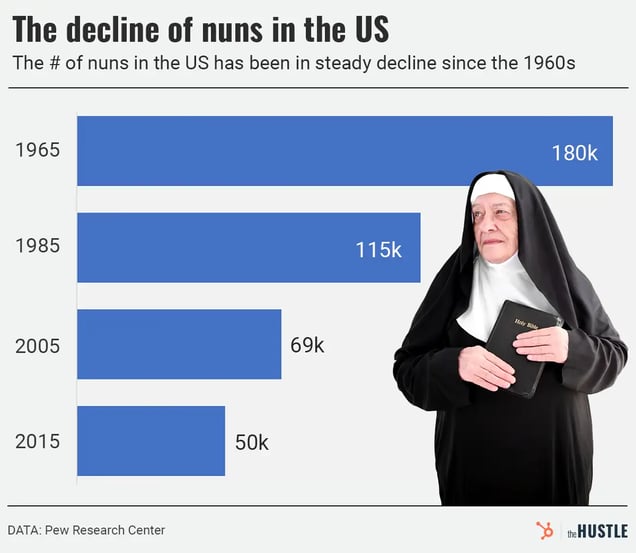

Many churches, looking to cut back on expenses, were willing partners. A broader decline in nuns also meant fewer ties between parishes and sisters than in past eras.

“The makeup of the parish priest might have changed in that some old-style priests wanted to support the nuns,” Starman said. “And then maybe a next generation later, it’s like, well, ‘What’’ economic?’”

Zachary Crockett / The Hustle

But instead of giving up, the Benedictine Sisters in Missouri doubled down.

- They purchased a Haas Baker, a 22-foot-long machine that produced a sheet of wafers every five seconds, allowing them to substantially increase their production capacity despite declining numbers of nuns at the convent.

- They responded to Cavanagh’s “mass marketing” with a letter-writing campaign of their own, asking every bishop in the United States to consider buying breads from religious communities.

In June 1992, the Benedictine Sisters organized a communion wafer summit, inviting the remaining convents that baked bread and even the secular market leader, Cavanagh.

The summit brought more awareness to the nuns’ business and helped the Benedictine Sisters win the rights to make 1.5m wafers for a 1993 festival in Denver featuring Pope John Paul II.

The Benedictine Sisters of Perpetual Adoration could bake 5k sheets of wafers per day on their Haas Baker. (Courtesy of the Benedictine Sisters of Perpetual Adoration)

Business kept growing. To handle increased orders, the sisters hired a dozen outside employees to operate the machinery when they were busy with praying and other duties.

Cavanagh may have had the advantages in marketing, pricing, and packaging, but the nuns separated themselves by emphasizing the traditional, religious style of their work.

“Our slogan [was] ‘Made by consecrated hands,’” said Sister Jane Heschmeyer.

In the late ’90s, the Benedictine Sisters sold ~130m wafers annually. That gave them ~10% of the altar bread market, making it by far the largest religious producer and one of Cavanagh’s most significant competitors.

But the sisters didn’t think about the competition. According to Starman, they just wanted to sustain the community by performing “reverent” work. Much of their profits went to their almsgiving commitments.

Opposite Cavanagh, the Benedictine Sisters emphasized the use of their hands as they baked bread. (The Hustle)

Like any good small business, the nuns continued to experiment, too.

In the early 2000s, Sister Lynn D’Souza, who had a science background as a biochemistry graduate of Texas A&M, tried several low-gluten recipes on a waffle iron. It was a challenge because the church stipulates that every wafer must contain wheat.

Eventually, D’Souza discovered a mix that wasn’t too sticky and was just airy enough. It met the requirements of the Roman Catholic Church, and the Baking Institute of America found it contained less than 0.001% gluten.

The Benedictine Sisters had once again found another way to differentiate themselves: They started to produce the world’s first low-gluten communion wafer approved by the church.

Losing the best altar breads

The Sisters worked through World War I, the Spanish flu, and World War II. In fact, the Tucson branch of the order shipped free breads to soldiers fighting in the Pacific.

But March 2020 brought a new challenge.

Parish after parish closed its doors as the country responded to the covid-19 pandemic. Suddenly, almost nobody was attending church, and demand for communion wafers dried up entirely.

The nuns halted production and furloughed their employees. (Being friendly nuns, they continued to pay the workers, despite them not working any hours.)

The Sisters’ base had slipped since the ’90s because of parish closures and the continued dominance of Cavanagh, although they were still producing ~60m wafers per year. By late summer 2020, when some parishes reopened, they were selling ~20%-30% what they had in 2019.

In addition to covid-related issues, the nuns knew they would soon have to replace their cooking equipment and find a new whole-wheat supplier.

“It was like, ‘I think this is the Lord telling us it’s time to close,’” D’Souza said.

Sister Lynn D’Souza helped perfect the Benedictine Sisters’ low-gluten wafer recipe. (The Hustle)

The Benedictine Sisters sent letters to every client, explaining they were shutting operations. With a top competitor out of the game, Cavanagh instantly assumed a larger share of the market.

But the Benedictine Sisters don’t blame Cavanagh.

They maintained a successful business for many years in the company’s shadow. Now they distribute Cavanagh wafers to hundreds of parishes and continue to produce and sell their own low-gluten wafers, a far-smaller operation.

Still, the absence of the Benedictine Sisters leaves just a handful of convents making altar breads in the United States and fewer nuns practicing a trade that sustained them for generations.

“For me, it just speaks to the broader loss of religious life in our culture,” D’Souza said. “It’s a loss, and it’s probably real subtle… but I think just with the spiritual presence, and the power of prayer and all of that, less of it is not necessarily a good thing.”

At the very least, as when any market consolidates under a monopoly, there’s now less variety in the world, a sad reality for many of the nuns’ supporters.

Father Stephen Siebert, a priest in Colorado, was a devout client of the Benedictine Sisters for years. He told The Hustle he was always impressed by the available colors and sizes of the Sisters’ wafers and how the wafers managed to stay intact at high altitudes.

When the Sisters sent him a letter notifying him they were ceasing production, Siebert wrote back to say they made the best altar breads he ever had.

“And in my unbiased opinion,” D’Souza said, “he was correct.”