Inside an 8k-foot converted airplane hangar in Micco, Florida, the Dr. Frankenstein of automobiles summons his newest creation to life.

The space is littered with giant styrofoam blocks, fiberglass molds, sheet metal, and the guts of chopped up chassis; soon, these components will be crafted into one-of-a-kind vehicles with names like Moonraker, Dimensia, and Slash.

For 20 years, Mike Vetter has been building some of the world’s most unique cars. His creations, which sell for as much as $225k, have made him a millionaire.

And it all began with a crazy thought he had when he couldn’t afford to buy his dream car: What if I build it myself?

The road to replica-car riches

The child of an overseas US Department of Defense employee, Vetter spent his youth bouncing around Southern and Western Europe. As a teen in Germany, he developed a deep passion for state-of-the-art vehicles.

“I lusted over Lamborghinis,” says Vetter. “My dad would say, ‘That thing costs more than most people’s houses; you’ll have to work very hard to have one of those.’”

After finishing high school, Vetter briefly tried his hand at a computer science degree but failed most of his classes. When his sister moved to Florida in the early ‘90s, he decided to tag along and enroll in a community college business program.

While in school, he took a trip to one of the largest classic car shows in the US, Daytona Turkey Run, and spotted an item that would change his life: The fiberglass body shell of a Lamborghini Countach.

Vetter had inadvertently stumbled upon what’s known as the kit car industry, a community of people who build replicas of high-end luxury cars — typically by affixing a reproduced fiberglass body (in lieu of sheet metal) on top of the chassis and mechanics of a lower-end car.

“I didn’t know anything about kit cars, or fiberglass, or anything of the sort,” says Vetter. “But something just clicked in my head. I saw this beautiful Lamborghini body, and I just had to have it.”

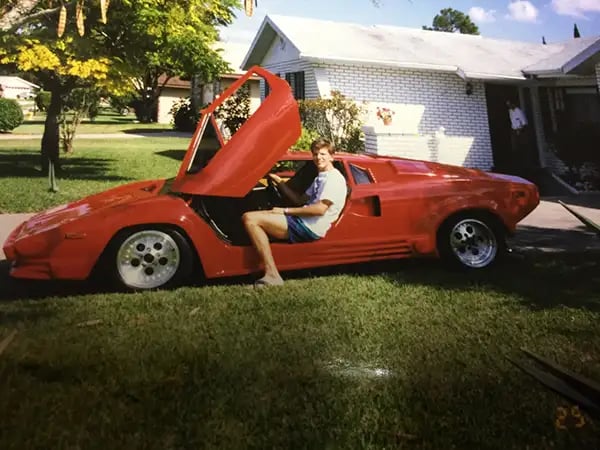

He purchased the body for $2.5k. Then, in the garage of a small house he shared with his sister, he resolved to build his dream “Lamborghini.”

Building a Lambo from scratch

Though Vetter had no idea how to build a car, he’d always been “technically and mechanically inclined” — the kind of kid to take apart a broken microwave and fix it. He was also resourceful, curious, and determined.

His first course of action was to find the right car for the chassis of his Lambo. After browsing through a copy of Kit Car Magazine, he settled on a Pontiac Fiero, an affordable mid-engined sports car with good guts. He found one nearby for $1.7k.

The next step was to remove the body and “stretch” the chassis (a lengthening process used to make the car look authentic). He had that done at a hot rod shop for $800.

Vetter had never used a reciprocal saw or a welder but he bought the tools and learned on his own. At every juncture, he encountered some kind of issue. “Something as little as the door hinges was a huge task,” he says. “I bought hinges from Home Depot, hinges from car magazines. Finally, I was forced to make them myself — 5 times.”

With two trunks, two hoods, and wing doors, the Lamborghini Countach was just about the hardest kit car imaginable to build. The body of the car was so riddled with contours that professional painters refused to touch it (Vetter eventually had to learn himself, with the help of a 60-year-old mentor).

He worked on his car late into the night while juggling business classes and odd jobs at Burger King, an auto shop, and a local movie theater.

A year and a half — and some 2k hours of labor — later, he finally finished.

“I built that first one with none of the required tools, and no knowledge of the subject at all, but really just the motivation and desire to have this vehicle,” he says.

In 1996, Vetter, fresh out of college and hurting for cash, decided to see if he could sell it for a profit. All in, he’d spent $12k to build it.

Around town, the car had become a photo-courting spectacle — but car pros wanted nothing to do with it. “I took it to some dealers and they said, ‘Oh, that thing’s worth less than when it was a Fiero! You’ve messed it up!’” recalls Vetter.

Instead, Vetter took out a $40 ad in a car trade magazine; within two weeks, he sold the car for $28k, more than double what he’d put into it.

After the sale, Vetter realized that he might be able to make a better living flipping cars than he could with his $18k/yr movie projectionist gig. So, he decided to go all-in.

The kit car business

At the time, the Nicolas Cage action flick, The Rock, had just come out. The movie featured a yellow Ferrari 355 that caught Vetter’s eye.

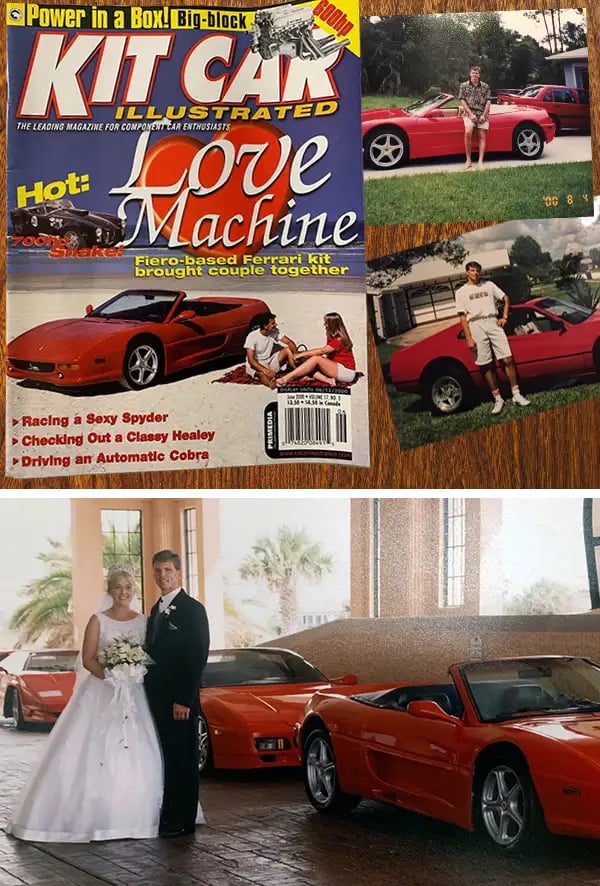

He found a Ferrari body kit in New Jersey, bought (and tore apart) another Pontiac Fiero, and repeated the process. This time, he completed the car in 4 months — a small fraction of the time it took to build his Lamborghini — and spent just $7k.

This time, he found two willing buyers; one bought the Ferrari for $21k; the other ordered a second car for $20k.

“I realized then that I could make this into a business,” says Vetter.

At the time, kit cars had a negative connotation. Most were poorly done and weren’t true to all the detailing that made exotic sports cars special. But Vetter’s creations were different.

“I could tell right away when a car didn’t look right,” he says. “I could see if the headlights were 4 inches too high on the hood. I could see if the windows were too small. I could see if the windshield was curved or not. A lot of people cut corners on the details and gave the kit car industry a bad name; I saw an opportunity to fix that.”

Vetter’s Ferrari replicas soon earned him a place on the cover of Kit Car Magazine, and, by default, a reputation as one of the more skilled artisans in the business.

By the early 2000s, Vetter and his wife (who he met at a car show) had streamlined the process and were producing a new exotic replica every 45 days, for as much as $60k apiece. The couple even sold a “Lamborghini” to pro golfer John Daly.

But just when things started heating up, a big problem arose.

When Ferrari comes knocking

Vetter had always been extremely cautious about how he marketed his cars.

“I never called them Ferraris,” he says. “I’d always say ‘Pontiac Fiero European styled to look like a Ferrari.’ I wasn’t trying to [dupe] people. Ferraris were $100k+ cars; I was selling mine for a fraction of that.”

Ferrari didn’t see it that way: The luxury car titan sent Vetter a cease and desist letter. Lamborghini soon followed suit.

When Vetter received the first letter, he had 20 Ferrari and Lamborghini kit cars ready to sell in his shop. He noticed he had 30 days to respond to the letter, so he’d wait until the 29th day to respond; the back-and-forth legal process bought him about 6 months of time, allowing him to offload his inventory.

Ultimately, a judge looked at photos of Ferrari’s patents and Vetter’s creations side by side, deemed that Vetter was infringing on the company’s trademark, and barred him from building any more cars.

His kit car business busted, Vetter made an executive decision: He’d design and build his own cars instead.

A UFO on the streets

In 2008, Vetter set out to build a custom-built car like no other ever made — something “people wouldn’t even believe” when they saw it on the street.

Over the years, he’d moved his operation to a series of bigger and better shops, eventually settling in a massive airplane hangar in Micco, Florida. He’d hired a 5-man crew and taught himself how to do everything from building his own fiberglass body shells to fabricating his own headlights. He had all the tools in place to design and build his own custom cars from scratch.

Vetter began by sketching out a concept of what he wanted. He purchased an enormous chunk of styrofoam and hand-sculpted it into the body shape he wanted. From this body, he fashioned a set of fiberglass molds, which he affixed to the guts of an old Chevy Cobalt, which he cut in half and stretched.

He dubbed the final product the Extra Terrestrial Vehicle (ETV).

With its futuristic design and eye-catching originality, the ETV immediately commanded attention. It generated its own press, drawing massive crowds at car shows.

Vetter put it up for sale on eBay and it became one of the “most-watched” cars in the history of the platform, eventually selling for $190,000. Over the next few years, Vetter built 7 more and sold them each for $100k+.

A very niche business

Today, Vetter’s company has sold more than 300 custom-built cars to buyers all over the world.

His cars range in price from $125k to upwards of $225k. On a typical $125k build, he’ll spend $47k on parts, a good enough margin to net a comfortable living.

When he first began building car bodies, the process would cost him $35k and take 6 months working by hand. Now, utilizing routing machines and 3D-modeling programs, he can produce one for $25k in a few weeks.

He says he gets hundreds of requests to build custom cars but turns many of them down: “I could grow bigger, but I try not to. It’s a quality control thing.”

“Generally my customer is the gentleman who has already owned several Ferraris and wants something his neighbor can’t go out and buy,” says Vetter. Many of his clients fear being mocked in their exotic name-brand cars. But with the concept cars, there’s no stigma: “Instead of ‘Look at this jerk in his Ferrari,’ it’s ‘Whoa, that thing is crazy!”

Vetter has also caught the attention of Hollywood studios, which occasionally hire him to build custom cars for blockbuster films.

“Warner Brothers wanted 3 purple Lamborghinis they could wreck in Suicide Squad,” he says. “I told them I couldn’t build them because of lawyers, but I was able to talk them into another custom build.”

The 47-year-old claims to work 80 hours a week and still loves what he does.

Recently, he purchased a second 8,000-foot airplane hangar next to his workshop and converted it into his “dream home.” It has an open floor plan that looks like something out of The Jetsons.

A maroon Extra Terrestrial Vehicle is stationed in the middle of the living room.